A holistic approch

To sustainability.

SUPPLIER DUE DILIGENCE

Raw material procurement and due diligence

The availability of quality raw material is crucial for our business. We currently have more than

500 direct raw material suppliers, with roughly 350 of them being local. We encourage local

sourcing with the goal of improving the local economy, streamlining logistics, and reducing

transportation and its accompanying environmental impact. The majority of our packing materials

come from sources within a 10-kilometre radius of our manufacturing facilities.

As a part of due diligence with respect to its raw material supply, company has introduced

mechanism to evaluate local vendors based on various criteria such as compliance with statutory

requirements, environment management system, safety management system, sourcing from conflict

region etc.

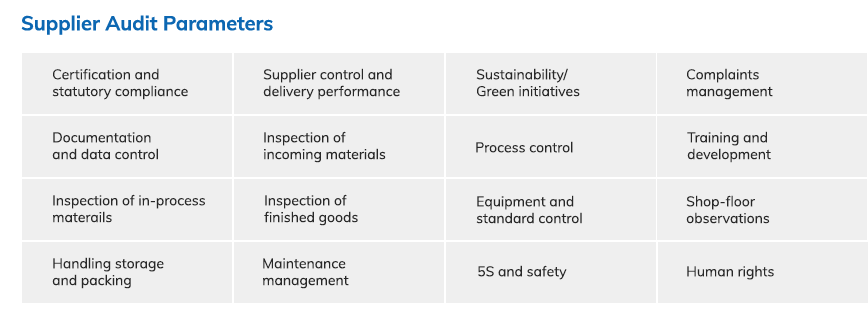

As part of our due diligence, we conduct supplier audits at regular intervals to ensure

operations of highest standards. We have a comprehensive audit system to evaluate suppliers

through factory visits. In FY 2021-22, we conducted supplier audits for 13 existing packaging

material suppliers. Apart from this, joint testing was also carried out for improving quality

with 9 vendors. During the year, 7 new vendors were incorporated in our approved manufacturer

list, and all of them were assessed and regularised. These included local and international

vendors.

*Data as on 31st March 2021

Building a sustainable supply chain

As part of our sustainable supply chain strategy, we regularly engage with our supply chain partners to sensitise them on the KNPL’s Code of Conduct for fair and transparent dealings, protection of human rights, appropriate behavioural norms and best ethical practices. In addition, we also conducted virtual training and awareness sessions on ESG which highlighted KNPL’s journey and our expectations from our value-chain partners towards achieving ESG excellence.